About

TirolWool

Last spring, Glorija Blazinsek and Giacomo Frison from Altripiani set off to travel "The Wool Road".

The project

About TirolWool

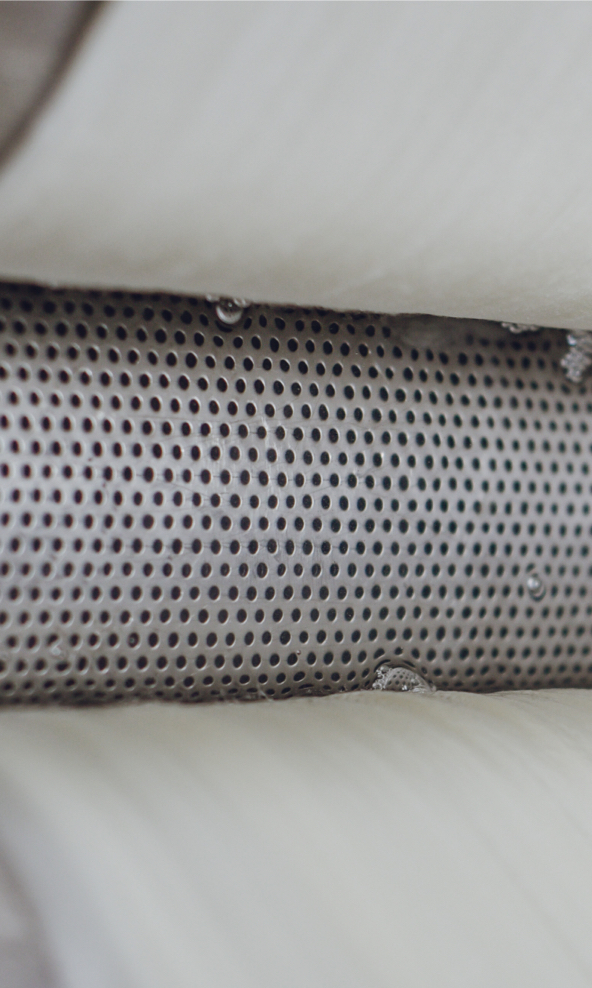

While they didn't go far, Glorija and Giacomo spent several months travelling around Italy to research all of the processes that go into making TirolWool®, which we use in our technical garments. Their story begins amidst the alpine pastures of South Tyrol and the stables upon the valley floor. Glorija and Giacomo set up base in Biella, Piedmont, in one of the most cutting-edge textile districts for wool selection, washing and carding. Ceaseless in their pursuit of the bales of wool, the two ascended to Varese in Upper Lombardy, close to Lake Maggiore. Hundreds of reels of wool are made there daily with an abundance of precision and passion.

Next, they moved on to visit a small company in the Marche region at the foot of the Sibillini Mountains, where a group of knitters gracefully and frugally create every accessory. Finally, they travelled to the Veneto region. The duo’s first stop there was Cittadella, where they filmed the technologically advanced machines used to make TirolWool® Responsive. They finished up in Montebelluna with a team of experts, where they talked about the end product as well as new prototypes for the future.

About TirolWool

The Process

The Protagonists

Discover our TirolWool® products